Lockout / Tagout

- SPI9/19/2025

10 Essential Tools for a Successful Lockout Program

Each year, an average of 1,000 work accidents occur in Quebec. Of those accidents, there have been 4 deaths caused by inadvertent releases of hazardous energy during installation, maintenance, repairs or unblocking work. Most of these accidents could have been avoided by the application of proper prevention measures such as the implementation of a lockout program.

- SPI7/13/2023

Enhancing Workplace Safety: The Advantages of Lockout-Tagout

In today's industrial and manufacturing environments, ensuring the safety of employees during equipment maintenance and repairs is paramount. One essential safety procedure that has repeatedly proven worthy is lockout-tagout (LOTO).

- SPI6/7/2017

Individual lockout versus group lockout: what are the differences?

The purpose of lockout is to control hazardous energies associated with equipment and machines to prevent any release of uncontrolled energy, and therefore any subsequent injury during maintenance or repair work. Lockout is a working method that drastically improves the safety level of workers.

- SPI11/3/2016

Lockout: Social Responsibility, Productivity and Reputation of Companies

The 2014 statistics of The Association of Workers’ Compensation Boards of Canada established that a total of 2.5 fatal accidents occur in Canadian workplaces each day. In addition to these deaths, 239,643 accident reports or work-related illnesses are added daily to that number. Severe accidents are often caused when a body part makes contact with live or mechanical parts of moving equipment, hazardous chemical products or pressurized fluids that are suddenly released.

- SPI10/1/2014

Are you afraid of implementing a lockout system?

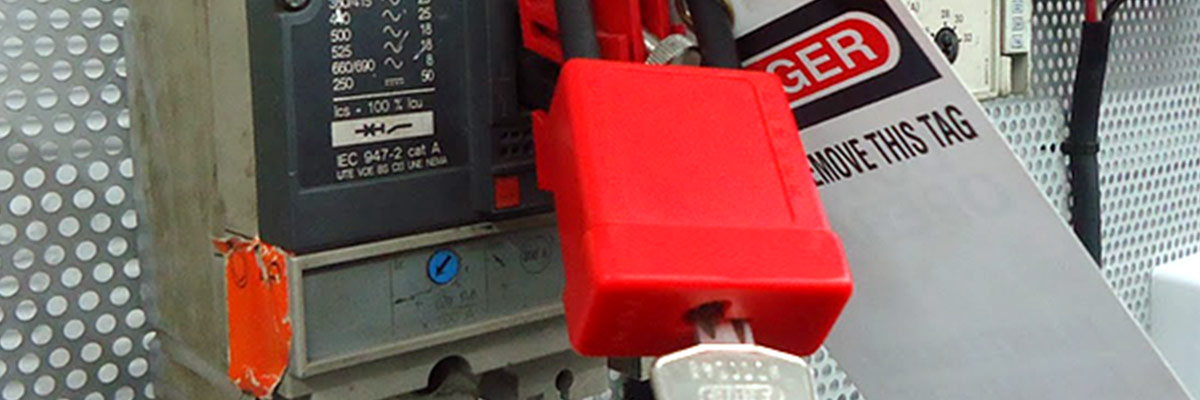

Lockout is an essential component to eliminate accident risks by cutting out all hazardous energy sources from the equipment. You also need a lockout procedure, a reference document indicating a series of vital information such as the lockout work sequence and the unlocking procedure.

- SPI8/14/2014

Lockout saves lives

Proper lockout ensures the safety of employees that operate equipment. The death rate is too high when the implemented system is defective.

- SPI4/2/2014

The lockout standard targets your mobile equipment!

Did you know that Standard “CSA Z460”, on the control of hazardous energy and lockout is now applicable to your mobile equipment? A recent addition to this standard’s scope could have a significant impact on your work methods.

- SPI3/5/2014

The 3 Most Common Mistakes When Purchasing a Lockout Software

Many believe that the implementation of a management software will solve all their problems. But is it really the case? Obviously, the answer is no. First, you must know the processes already in place and how they affect the employees. This article provides useful avenues for reflection.

- SPI11/6/2013

Review of the CSA Z460 Canadian Standard on Lockout/Tagout

In Canada, 2005 marked a turning point regarding the control of hazardous energy. The “Control of hazardous energy – Lockout and other methods” standard was edited. Its implementation aimed toward the harmonization of lockout practices in Canada and Quebec. Did this standard deliver its promises? And what about its application in 2013?

A major modification introduced in the new version concerns the scope of the standard. It now includes mobile mechanical equipme...

- SPI11/6/2013

Revision of the CSA Z460 Canadian Standard on Lockout/Tagout

In Canada, 2005 marked a turning point regarding the control of hazardous energy. The “Control of hazardous energy – Lockout and other methods” standard was edited. Its implementation aimed toward the harmonization of lockout practices in Canada and Quebec. Did this standard deliver its promises? And what about its application in 2013?

- SPI3/25/2013

Man versus Machine: lockout/tagout program for machinery

Small and large companies in the manufacturing industry invest tremendous efforts and money in modernizing their automated machinery. However, even if automation reduces the number of human interventions, it does not totally eliminate them, and workers are still facing hazardous situations. Do you have a lockout/tagout program and are all your lockout tags compliant and updated for all your equipment?